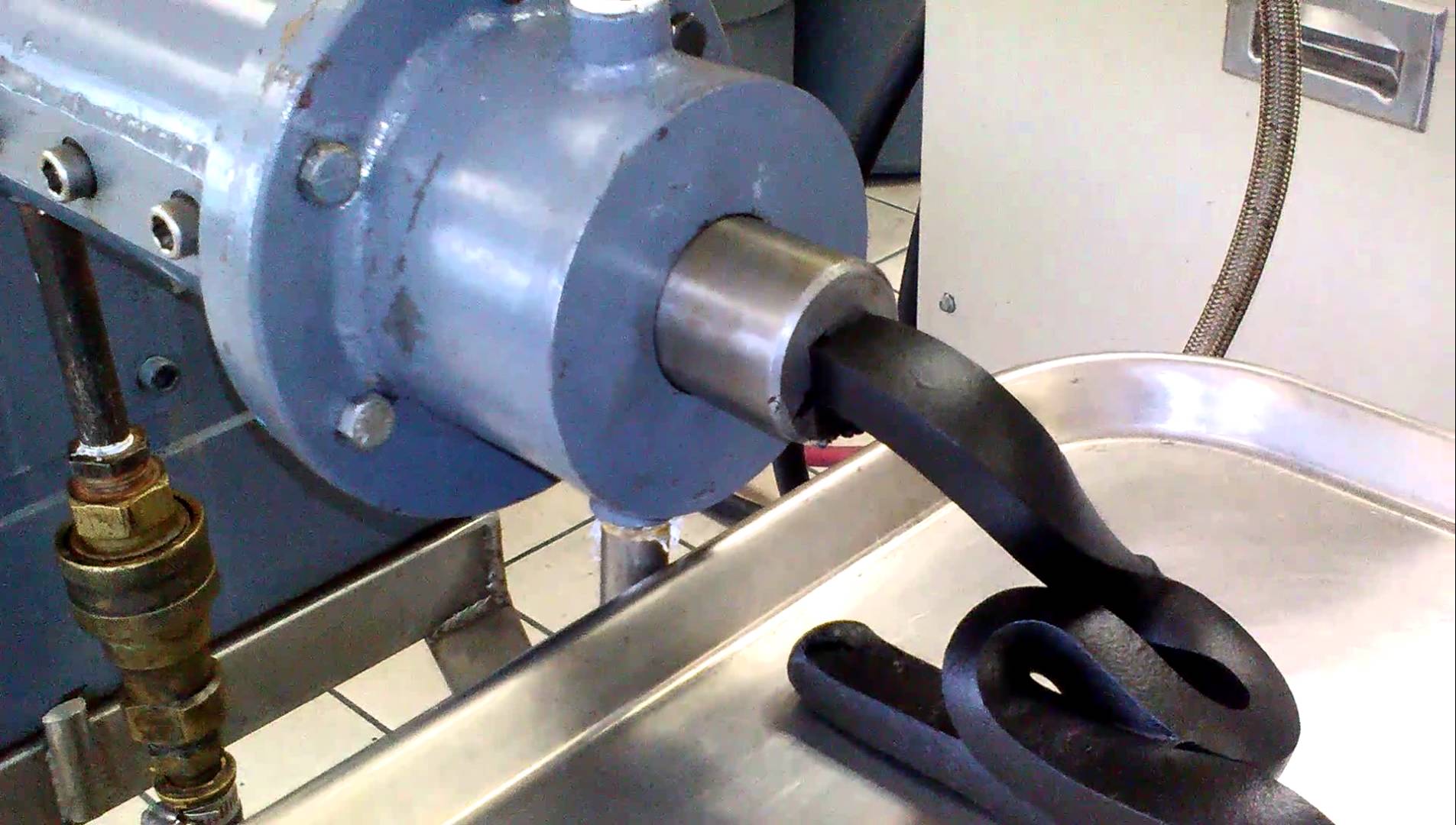

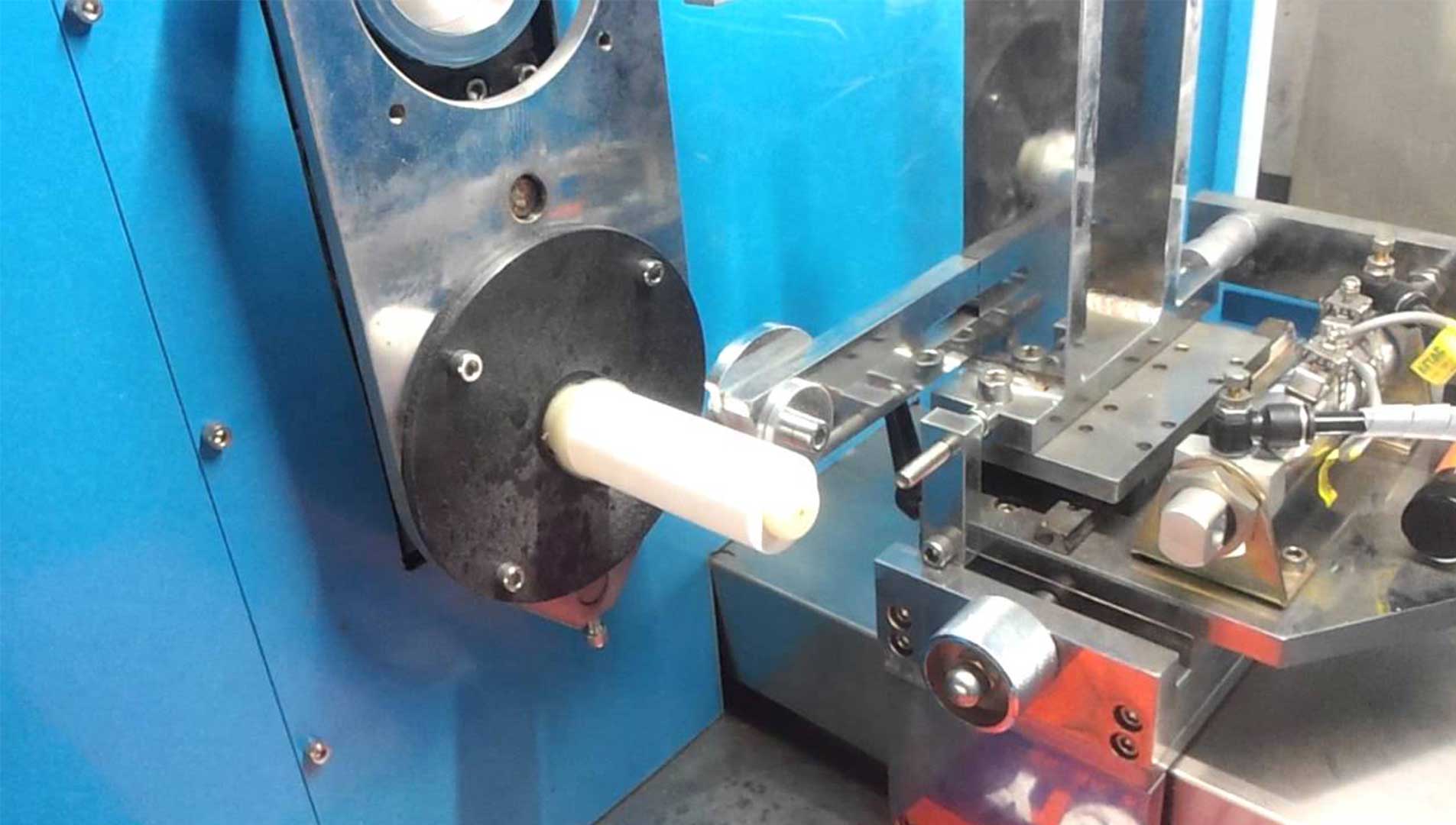

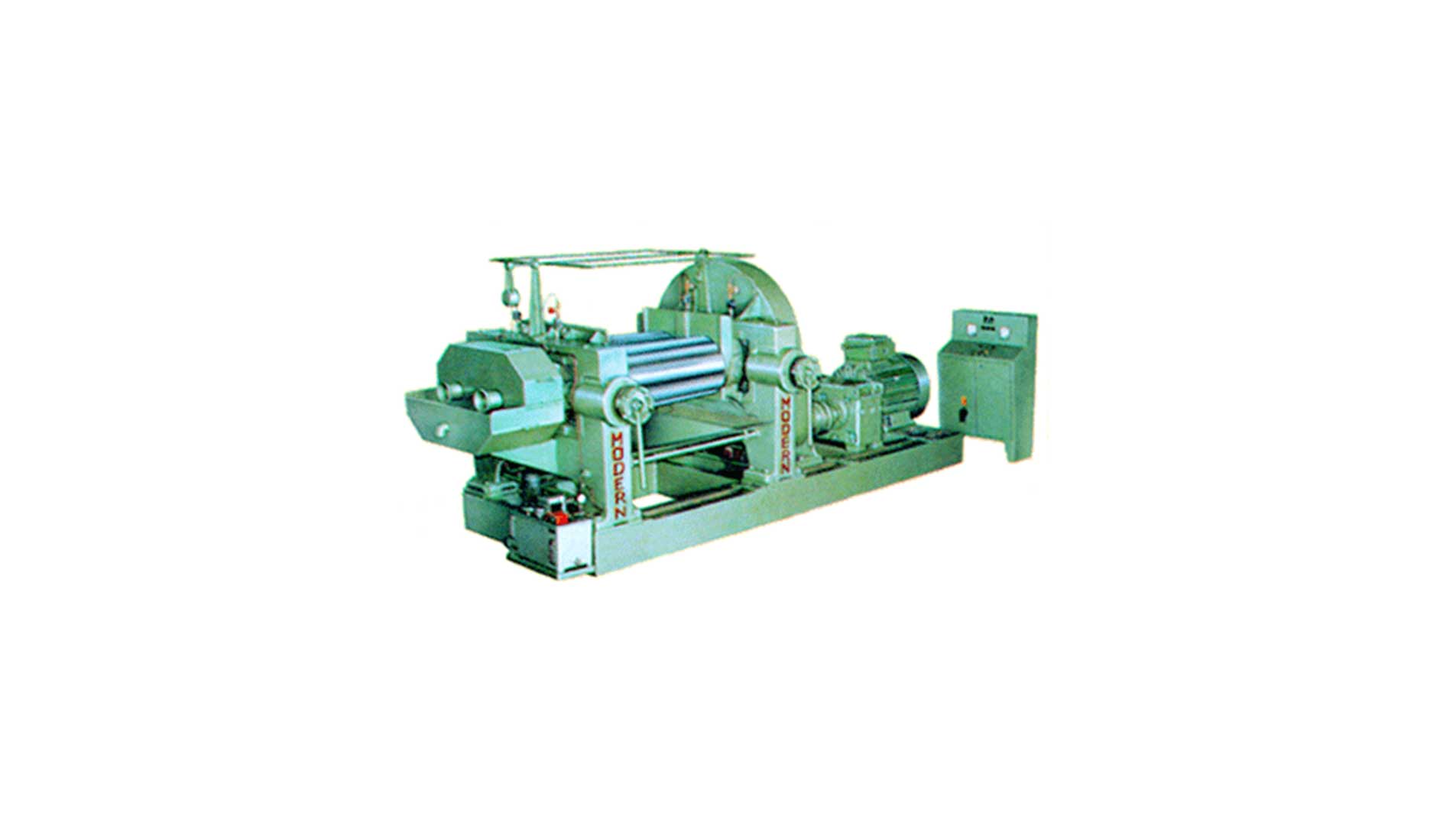

Extruder

Extrusion is the process by which a raw material is heated, pressurized, cooled and then forced through a die that forms the material into a new shape. Dies are tools that are specially designed to form a raw material into a new shape. The material is then completely cooled and hardened.